08 Sep wood heater flue

Wood Heater Flue Kit

Wood heaters and wood stoves all need a flue to exhaust the smoke out of the room, but it does more than just that.

It is an integral part of your wood heaters operation, its performance, the style it will give to your home and most importantly safety.

References

In Australia we share industry standards with New Zealand – the standard for wood heater flues is AS/NZ2918:2018.

Everything in this blog refers to this standard

For a Free download of Pivot’s Wood Heater Install Handbook – CLICK HERE

All wood heaters must be installed by certified wood heater installer and a certificate of compliance given. This blog is for information purposes only.

The design of any flue kit is for safety

- The inner working flue (called the active flue) temperature can vary from an average of 150°C to up over 500°C

- The flue going through the ceiling cavity (called the outer casing) needs to be cool enough to be considered safe

- the Australian standards testing is this outer temperature of the flue in the roof cavity must not exceed 80°C

- To cool this outer casing down to a safe temperature, this can be achieved by insulating the flue, or by air cooling the flue

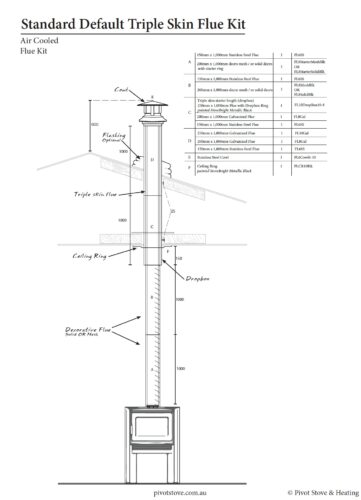

Flue Kit Type 1. Default Triple Skin Flue: Air Cooled flue system for wood heaters and wood stoves

This flue system has 2 separate parts;

- the flue in the room

- the flue in the roof

The flue in the roof

This part of the flue is called triple skin flue, and its the gap between the flue layers that allows air to pass through to cool this flue down

This triple skin flue this is made from:

- an active flue. 150mm (or 6″) made from stainless steel

- a second skin. 200mm (or 8″) made from galvanized steel

- and a third skin. 250mm (or 10″) made from galvanized steel

The air gap between these layers must allow 420ltrs of air to pass every minute to suck the heat away from the flue to cool the outer flue down to a maximum of 80°C

It’s this cooling of the flue that allows it to be installed as close as 25mm from timber in the ceiling cavity

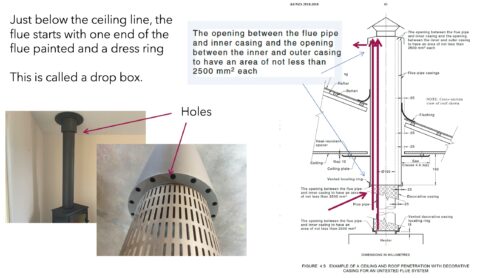

How the air enters the flue is though the air holes in the drop box.

These holes must have an area of 2,500mm2 to allow the correct amount of air to pass though the triple skin to cool the flue down

In the underside of the cowl, there needs to be the exact same area of open vents to allow this hot air to escape.

- The maximum amount of air that needs to be allowed to pass through these holes is 420ltrs per minute

- Note: this is amount of air flow calculated to 8% of the heat for your wood heater that is used to cool the flue down

Flue designs in the room

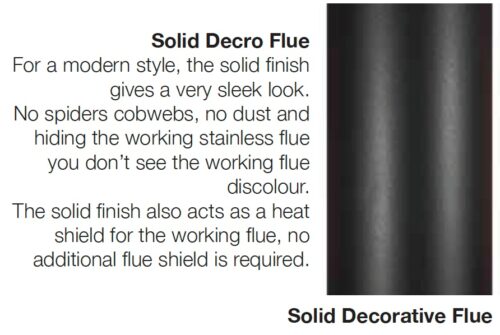

There are 4 main looks of flue in the room to choose from, all flues have a heat shield on the rear of the flue to deflect any radiant heat from the active flue away from the wall

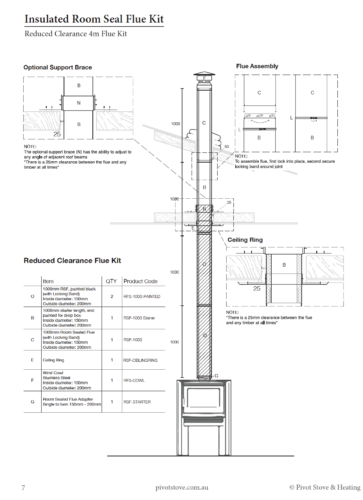

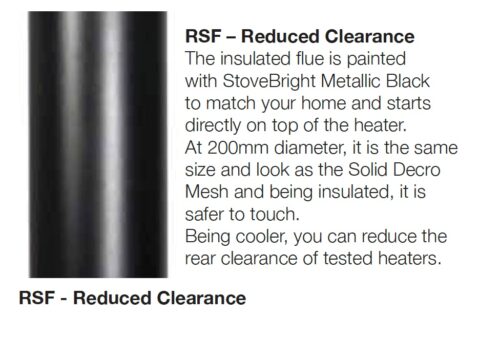

Flue Kit Type 2. Insulated flue kit: Room Seal Flue System for wood heaters and wood stoves

Insulated flue systems are the most common flue used in the world.

The flue uses ceramic insulation between the inner (active) and outer flue to reduce the outer flue temperature.

The insulated flue is made from:

- 150mm (6″) stainless active flue

- 25mm thick ceramic insulation

- 200mm (8″) stainless outer flue

The insulation between the active and outer flue reduces the outer flue temperature, so at a maximum active working temperature of 500°C – the outer 200mm stainless flue will only achieve the maximum required temperature of 80°C

- The cool outer flue allows this to be installed as close to 25mm from timber in the ceiling cavity

Flue designs in the room

Flue Height

The flue height on any wood heater or wood stove is critical.

How the air that your fire needs enters into your fire is actually drawn in by the flue.

This is what is called Flue Draft: the volatility of the Draft (or suction pressure in the flue) directly impacts the fires performance.

- not enough flue draft, the fire won’t catch correctly and will smolder and smoke

- too much flue draft and two things happen;

- You get a roaring fire.

- The flue draft actually sucks the heat away from the fire. This is called Lifting when the heat in the firebox is sucked into the flue (just like a vacuum) and you will get significantly less heat.

The Australian standards state:

The top termination of the flue from any wood heater must be a min of 4.6mtrs from the hearth (reference AS/Nzs 2918:2008 4.9.1.a)

Based that the height of an average height of wood heater is 600mm – a minimum flue kit length is 4,000mm.

The min working parameters of any flue system are

- minimum draft 12pa

- maximum draft 25a

- mean flue temperature 170°C

Flue kits that are 3,600mm (or 12′) in height no longer comply to the new standards

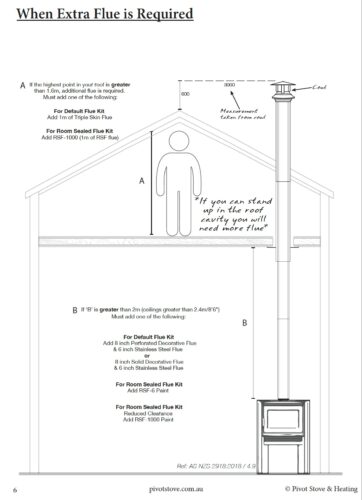

When extra flue is required

A standard flue kit is 4,000mm high and suitable for most standard homes

The issue is there is no standard home any more.

Flue in the room

A standard ceiling height varies between 2,400mm – 2,700mm

Based that in a;

-

- standard flue kit you get 2,000mm of flue in the room

- + the average height of a wood heater is 600mm

- + the additional drop box starts 150mm under the ceiling

- the maximum ceiling height a wood heater flue kit can do is 2,700mm

If your ceiling is higher than 2,700mm then you will need to purchase additional flue in the room

Flue in the ceiling

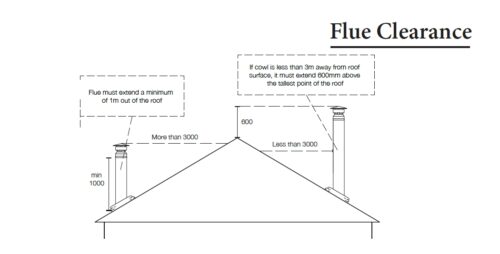

In a standard flue kit you get 2,000mm of protected flue (outer flue) and the top of this must finish at either:

- 3,000mm away from any roof line

- OR if you cannot get the flue to finish 3,000mm away from any roof line – extend the flue so it terminated 600m above this roof line

- Rule of thumb: if you can stand up in the center of your roof cavity, you will need additional flue

Flue Clearances

The termination (finishing height) of your cowl is critical to the performance of your wood heater.

The measurement of termination is taken from the cowl.

The exact rule is “termination of the exhaust outlet” so this measurement should be taken from the end of the actual flue

Different types of cowls for wood heaters

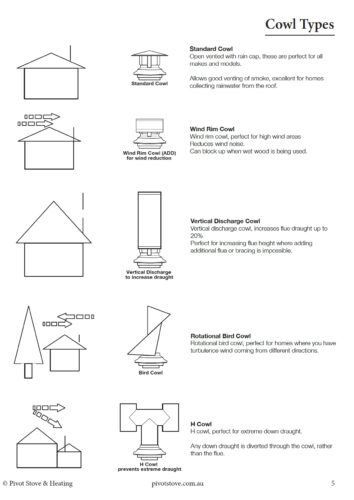

Most wood heater flue kits are supplied with what is commonly known as a “China-mans” cowl.

This style is perfect for all makes and model wood heaters and allows good ventilation of the smoke.

But sometimes there are other factors where this style of wood heater cowl is not suitable

- In windy area’s a Wind Rim Cowl (also called a Anti Down Draft”ADD” Cowl) is great to reduce wind noise

- In homes with very high roof lines / or for wood heaters or wood stoves that need that extra “umpf” a Vertical discharge cowl will increase the height of your flue + add a 20% increase in draft

- In homes that have wind coming from all different directions, a Rotational “Bird” cowl – also know as an “African Bird” is perfect

- In homes where you have excessive down draft, a H Cowl has top and bottom smoke discharge to stop the smoke being pushed back down your flue into your home

All wood heaters must be installed by certified wood heater installer and a certificate of compliance given. This blog is for information purposes only.

About the author

This blog was written by Greg Parker-Hill

Greg is a licensed plumber who has installed over 10,000 wood heaters and wood stoves in his 35+ year experience

The Parker-Hill family is Australia’s oldest heating family, trading as Pivot Stove and Heating co the family established this company back in 1876. 6 generations on, there is literally decades of experience that has been passed on

Sorry, the comment form is closed at this time.